As a technologically advanced product, hot-melt coating machines have achieved favorable development trends in the market. Unlike traditional foam coating machines, they offer high efficiency and rapid drying capabilities, significantly enhancing production output.

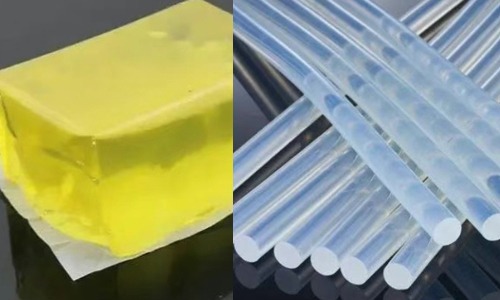

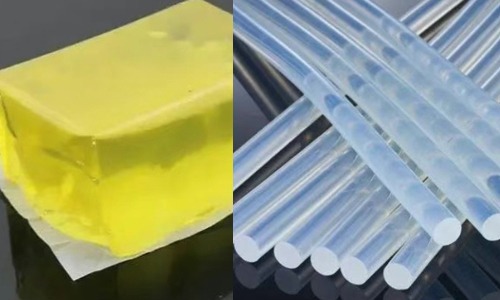

When using a hot-melt coating machine, it is essential to replenish adhesive promptly and, where appropriate, increase the coating volume. Insufficient adhesive application reduces adhesion and may result in poor lamination. To increase coating volume, you can:

Use an anilox roller with deeper cells;

Adjust rubber roller pressure;

Reduce contact pressure between the doctor blade and anilox roller.

For plastic film substrates, corona treatment before coating roughens the surface, improving adhesive adsorption and coating volume.

Secondly, special attention must be paid to drying temperature settings. Precise temperature control is critical to machine performance—excessive or insufficient heat compromises the bond strength of laminated films.

Excessive drying temperatures or exposure to high-temperature retort processing can carbonize the adhesive surface, degrading its bonding capability. Conversely, overly low temperatures lead to incomplete curing, weak adhesion, and subsequent bubble formation in laminated films, damaging product quality.

Jiayuan Machinery Hot-Melt Coating Machines

With 20 years of dedication to the coating industry, we offer:

Professional technical and after-sales service teams;

Machine operation training;

Raw material supplier coordination and supporting facilities.

Our integrated technical solutions establish a complete industrial chain for coating applications, ensuring seamless procurement for clients!

HOT LINE: 086-577-65159218

HOT LINE: 086-577-65159218