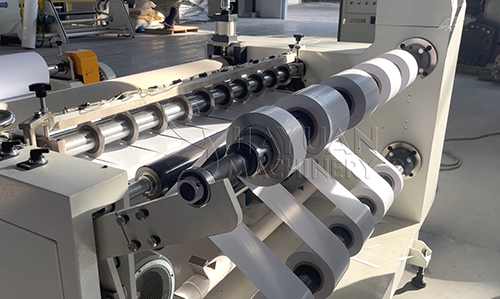

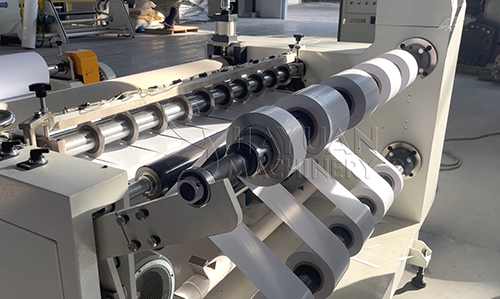

The Multi-function High-Precision Slitting Machine: Engine of Modern Manufacturing

Applicable Products:

In the intricate landscape of modern industrial production, efficiency is defined by precision and adaptability. At the core of countless advanced manufacturing processes stands a critical piece of technology: the Multi-function High-Precision Slitting Machine. This equipment is far more than a simple cutter; it is a sophisticated system engineered to meet the exacting demands of today's high-tech industries, transforming wide coiled materials into precise, narrow strips that drive innovation.

Unmatched Precision for Critical Applications

The defining characteristic of this machinery is its high-precision control. It is specifically designed for applications where tolerances are measured in microns and consistency is non-negotiable. The system's ability to maintain exact slit width, manage material tension flawlessly, and deliver a pristine edge quality is paramount. This is especially crucial in fields like new energy battery manufacturing, where the slitting of battery electrodes (anodes and cathodes) must be absolutely perfect. Any imperfection in the edge can compromise the safety, performance, and longevity of the final battery cell. Similarly, in the production of electronic materials and optical films, this precision directly translates to enhanced product performance and virtually zero material waste.

Engineered for Unparalleled Versatility

As the name suggests, multi-function capability is a cornerstone of its design. The true power of this machine lies in its adaptability. It is suitable for processing a remarkably diverse range of materials, including:

Films (e.g., plastic, protective, and packaging films)

Paper and Non-woven Fabrics

Metal Foils (e.g., aluminum and copper foil)

Composite Materials

Adhesive Tapes

This versatility is achieved through a modular design, allowing operators to adapt to different materials and techniques—such as longitudinal cutting, slitting, or shearing—simply by changing the blade modules. This drastically reduces changeover time and enables a single machine to serve multiple production lines or product types, offering a significant return on investment.

Driving Innovation Across Industries

The widespread applicability of the Multi-function High-Precision Slitting Machine makes it a vital asset across a spectrum of key industries. Its influence is felt in:

Printing and Packaging, where it ensures clean, sharp edges for high-speed packaging lines.

Medical and Protective Product Production, where it processes non-woven and composite materials for hygiene and medical devices.

Electronic Materials, where it handles delicate conductive and insulating films.

In conclusion, the Multi-function High-Precision Slitting Machine is an indispensable engine of modern manufacturing. It empowers industries to push the boundaries of what is possible by providing the foundational material processing capability that combines surgical precision with remarkable flexibility. As products continue to become smaller, smarter, and more complex, the role of this advanced slitting technology will only grow more central, solidifying its status as a pillar of industrial progress.

HOT LINE: 086-577-65159218

HOT LINE: 086-577-65159218